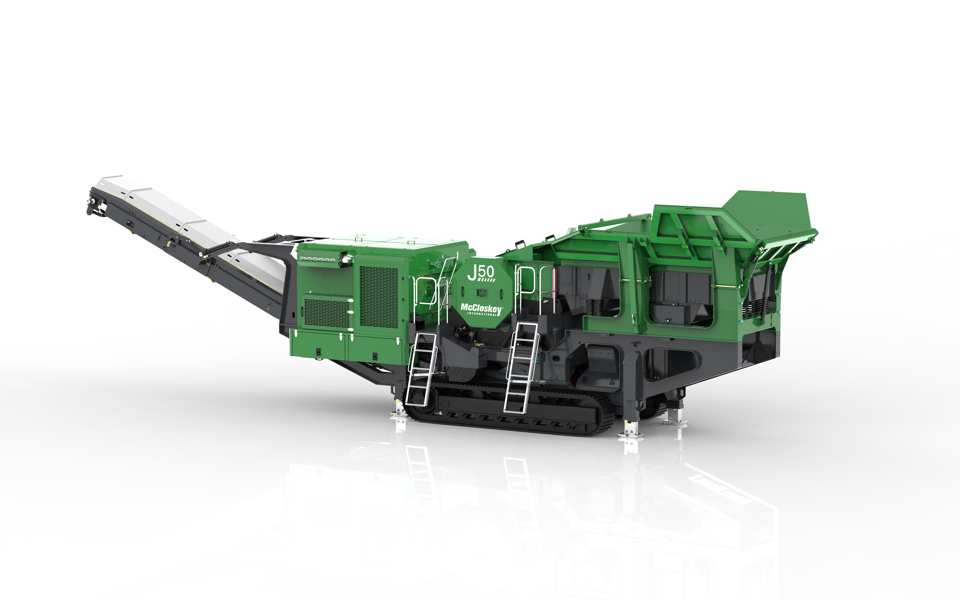

J50 Jaw Crusher

Features

1270mm (50”) x 735mm (29”) single toggle jaw

Track or Track c\w Wheel bogie

Integrated hydraulic folding hopper

Integrated hydraulic folding stockpiling conveyors

I-beam plate fabricated chassis construction

Large gap between crusher discharge and main conveyor feedboot

Open chassis design for ease of maintenance

Fast setup time

JAW CRUSHER RANGE CATALOG

With 1270mm (50”) x 735mm (29”) single toggle jaw (the widest jaw in its class), the J50 places McCloskey International at the fore of portable crushing machinery.

J50 Jaw Crusher

Maximum productivity is delivered through the enhancements to the jaw box including heavier flywheels and optimization for all crushing applications. The J50’s jaw speed leads to better reduction and material being processed faster through the crushing chamber.

McCloskey International has a proven reputation for designing quality, best-in-class equipment and the J50 Crusher brings even more power and productivity together in one machine. With its class-leading throughput and capacity and the largest stockpile height in its category the J50 crusher continues to push the boundaries of industry performance.

J50 Tech Specs

| Engine | 261kW (350Hp) – 265kW (361Hp) |

| Feed Opening | 1270mm (50”) x 735mm (29”) |

| Stockpile Heights | ————— |

| Main Conveyor | 4250mm (13′ – 11″) |

| Side Conveyor | 2584mm (8′ – 6″) |

| Pan Feeder | ————— |

| Width | 1164mm (45.8″) |

| Length | 3075mm (121”) |

| Prescreen Feeder (Option) | 1204mm (47.4″) x 2120mm (6’ – 11.4”) |

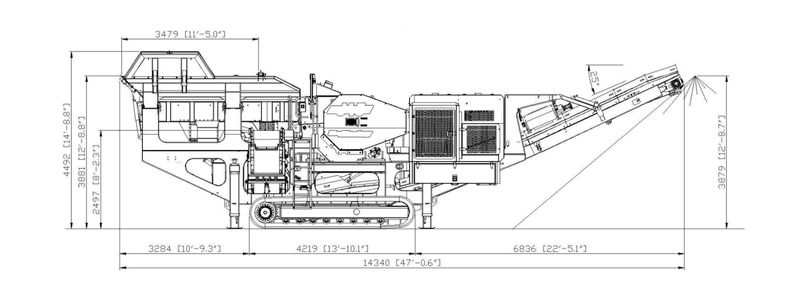

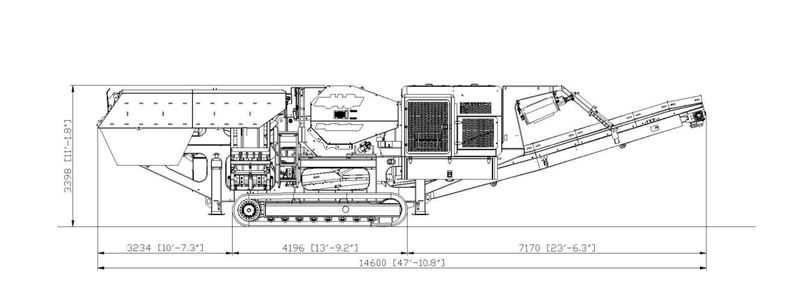

Transport

| Transport Height | 3.58m (11′ – 8.8″) |

| Transport Length | 15.44m (50′ – 8″) |

| Transport Width | 3.00m (9′ – 10″) |

| Weight | 58,700 Kgs (129,411 lbs) |

Options

Roll-in bogie system

50mm or 70mm Aperture Bofor

Main Conveyor Variable Speed Control

Hopper Extensions

Overband Magnet

Water Pump and Dust Suppression System

Diesel Refueling Pump

Square Tooth Quarry Dies

30mm Corrugated Dies

Multitooth Dies

30mm Corrugated Dies

Crusher Deflector Plate – Belt Protection