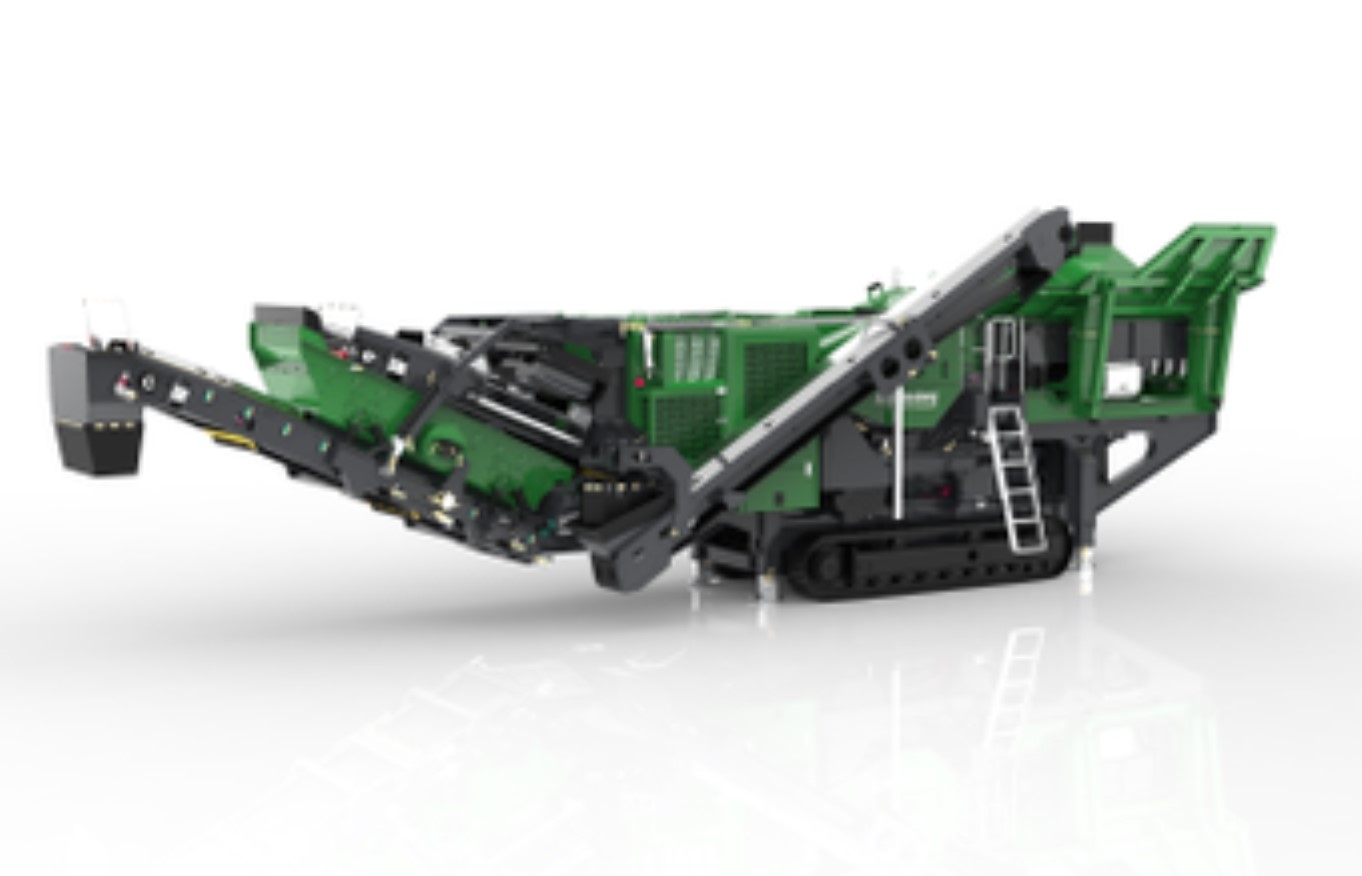

J45R Jaw Crusher

Features

1140mm (45”) x 688mm (27”) single toggle jaw

261kW (350Hp) C9 / C9.3 Cat engine

Track or Track cw Wheel bogie

Integrated hydraulic folding hopper

Integrated hydraulic folding stockpiling conveyors

I-beam plate fabricated chassis construction

Large gap between crusher discharge and main conveyor feedboot

Open chassis design for ease of maintenance

Fast setup time

JAW CRUSHER RANGE CATALOG

Both the J45R boast a high capacity hopper with close to 6m³ (8 yd³) capacity. The main conveyor features easy access heavy duty skirting and are closer to the ground level for ease of access and maintenance.

J45R Jaw Crusher

The J45R high capacity jaw crushers feature a true 1140mm (45″) x 688mm (27″) jaw. With both level and load sensors the J45R ensures the most efficient material handling across applications. The J45R features a heavy duty bofar design and pan feeder chutes with steeper angles to reduce material sticking.

The J45R offers the versatility of a recirculating system to product a crushed and screened final product with one machine. Alternatively, the return conveyor can be radialed to the side to stockpile rather than feeding back into the hopper.

J45R Tech Specs

| Engine | 205kW (275Hp) – 261kW (350Hp) |

| Feed Opening | 1140mm x 688mm (45” x 27”) |

| Stockpile Heights | ————— |

| Fines Conveyor | 2965mm (9’ – 9”) |

| Side Conveyor | 2500mm (8′ – 2.3″) |

| Grizzly Feeder | ————— |

| Width | 1064mm (41.9”) |

| Length | 4240mm (13’ – 11”) |

| Prescreen Feeder (Option) | 1.06m x 1.92m (41.9” x 75.5”) |

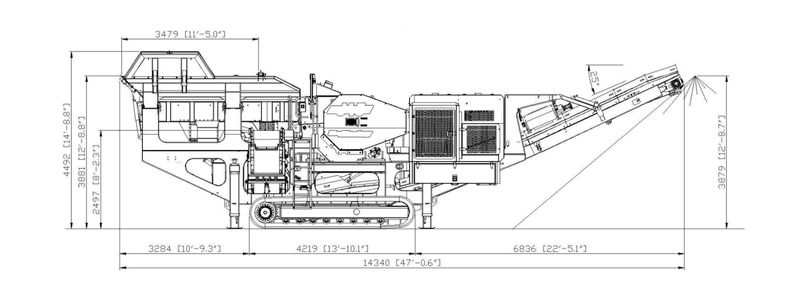

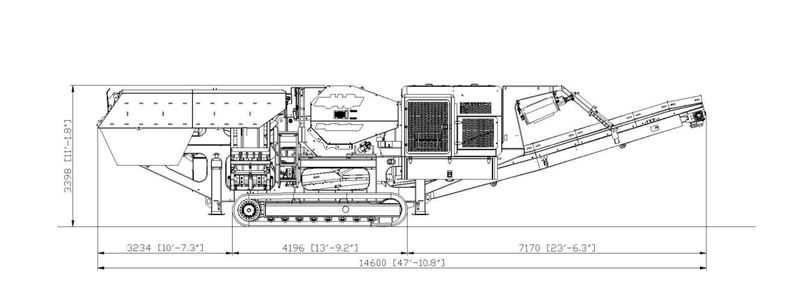

Transport

| Transport Height | 3.40m (11’ – 1.8″) |

| Transport Length | 15.42m (50′ – 3.2″) |

| Transport Width | 3.10m (10′ – 2″) |

| Weight | 56,000 Kgs (123,458 lbs) |

Options

Roll-in bogie system

50mm or 70mm Aperture Bofor

Main Conveyor Variable Speed Control

Hopper Extensions

Overband Magnet

Water Pump and Dust Suppression System

Diesel Refueling Pump

Square Tooth Quarry Dies

30mm or 50mm Corrugated Dies

Multitooth Dies

Crusher Deflector Plate – (Belt Protection)

Independant pre-screen and pan feeder