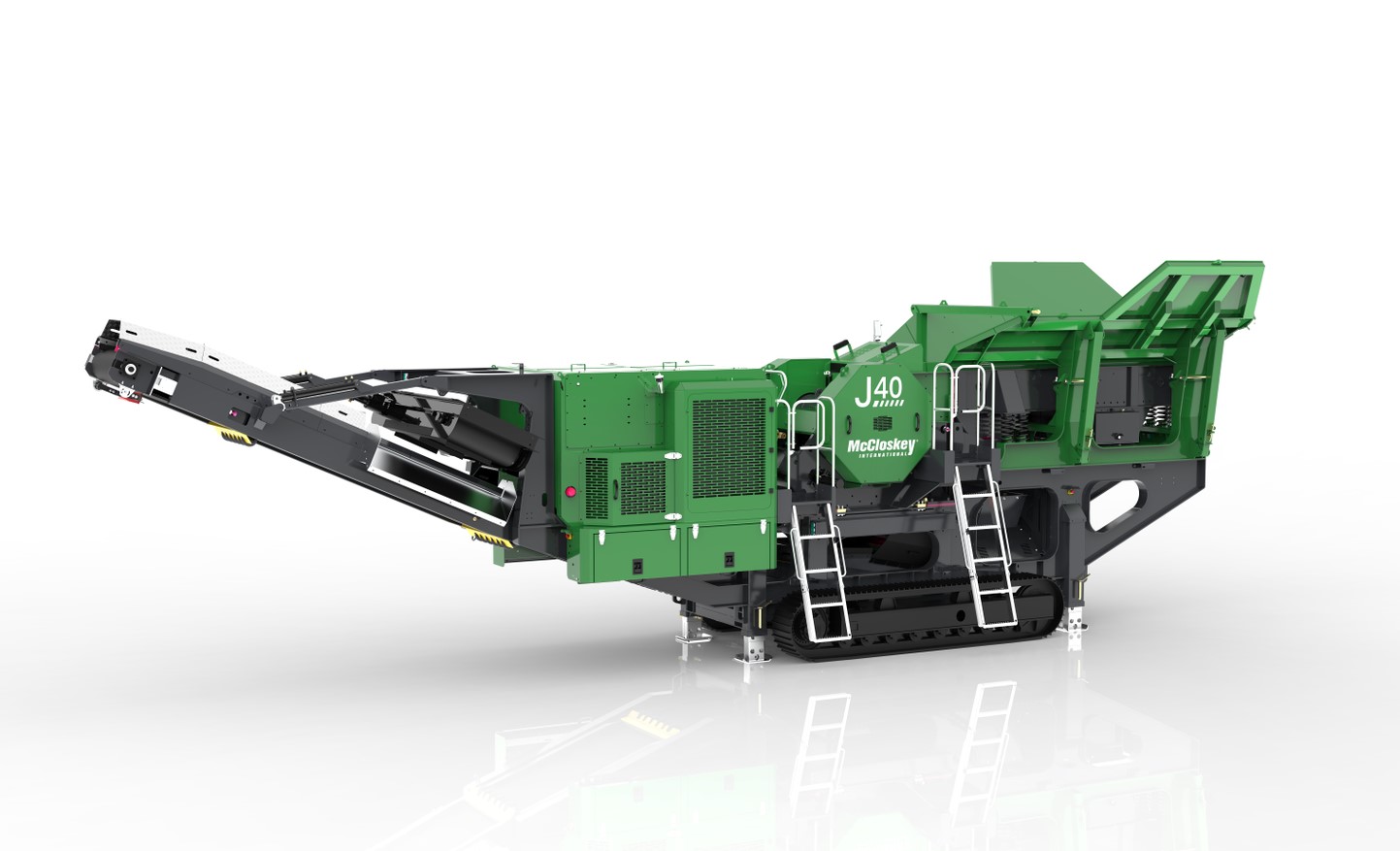

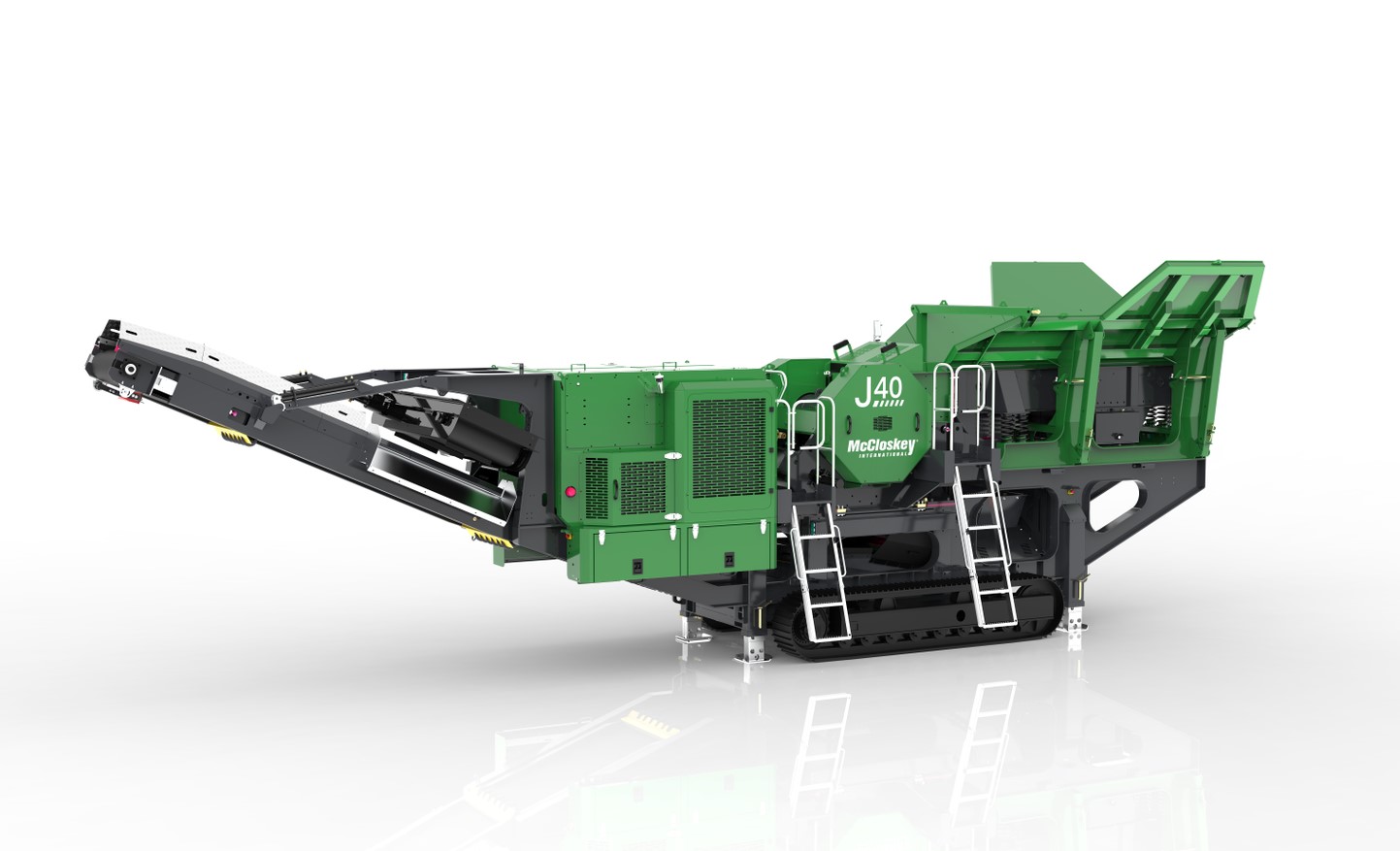

J40 Jaw Crusher

Features

True 1016mm (40″) x 610mm (24″) jaw

Hydraulic direct drive grizzly feeder

High capacity hydraulic folding hopper

900mm (36″) main conveyor

User friendly control panel

Ideal 2.5m (8′ – 2″) wide transport size

Optional overband magnet

10 minute set up time

JAW CRUSHER RANGE CATALOG

The J40 Jaw Crusher continues McCloskey’s focus on quality, durability, and productivity.

Rugged and versatile, the J40 offers the field-tested reliability required for the toughest projects around the globe.

J40 Jaw Crusher

With its heavy duty cheekplate design, 1016mm (40″) wide jaw and user-friendly control panel with excellent machine diagnostics, the J40 jaw crusher provides contractors with a highly portable option while meeting all production expectations. At 2.5m (8′ – 2″) wide, the J40 jaw crusher is ideal for applications that require a high degree of mobility.

Maximum productivity is delivered through the enhancements to the deep jaw box, including a faster jaw speed and a larger gap between the crusher discharge and main conveyor feedboot. The J40 retains the core values expected in a full size McCloskey jaw crusher, including high capacity production and heavy duty build, packaged for efficiency and mobility.

J40 Tech Specs

| Engine | 166kW (225Hp) – 187kW (25Hp) |

| Feed Opening | 1016mm (40″) x 610mm (24″) |

| Stockpile Heights | ————— |

| Main Conveyor | 3.46m (11′ 4.2″) |

| Side Conveyor | 2.50m (8′ 2″) |

| Grizzly Feeder | ————— |

| Width | 950mm (37.4″) |

| Length | 3840mm (12’ – 7”) |

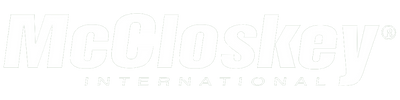

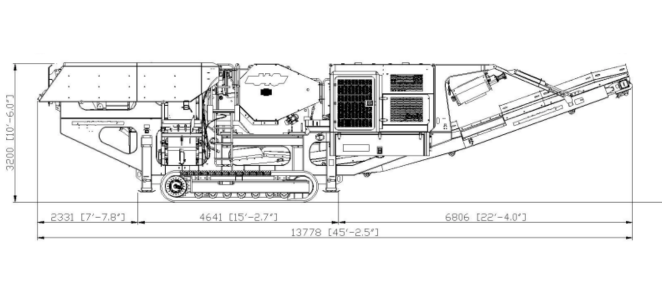

Transport

| Transport Height | 3.2m (10’ – 6″) |

| Transport Length | 13.78m (45′ – 2.6″) |

| Transport Width | 2.5m (8′ – 2″) |

| Weight | 36,940 Kgs (81,440 lbs) |