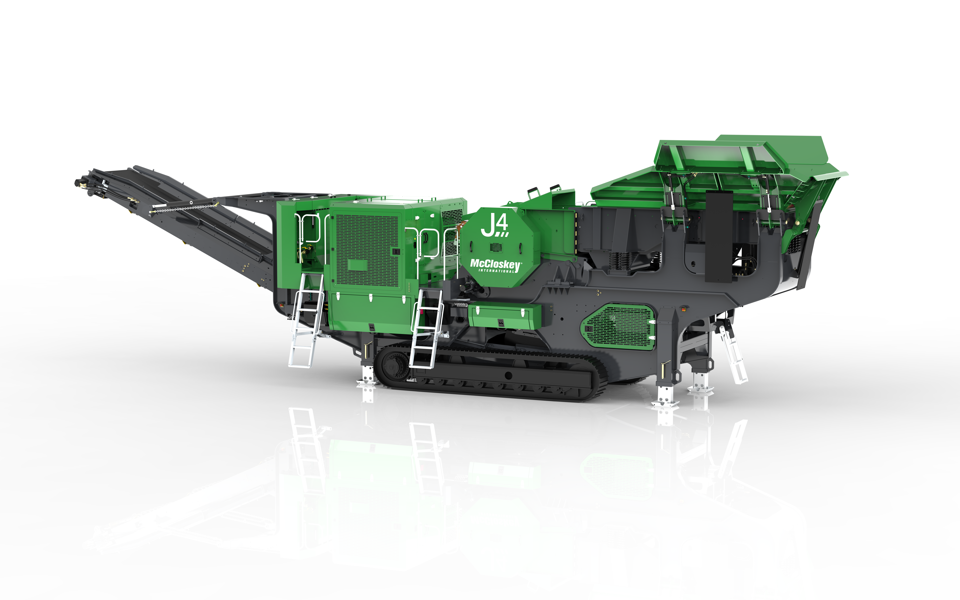

J4 Jaw Crusher

Features

1060mm (42″) wide x 700mm (28″) single toggle jaw

Choice of either a two deck or 1 1/2 deck recirculating system

Integrated hydraulic folding hopper & stockpiling conveyors

HD crawler tracks

I-beam plate fabricated chassis construction

Large gap between crusher discharge and main conveyor feedboot

JAW CRUSHER RANGE CATALOG

The new McCloskey® J4 builds on the robust design of the proven performance McCloskey Jaw crushers, and adds new productivity with an exciting line-up of features aimed at boosting productivity and offering enhanced durability across applications

McCloskey engineers designed the J4 to meet the evolving requirements of today’s projects and operations.

J4 Jaw Crusher

The large 1060mm (42”) x 700mm (28”) jaw chamber accommodates large feed sizes, contributing to higher production in material processing. The material path is enhanced with the adjustable speed 1064mm (41.9″) x 2215mm (7′ – 3″) double deck grizzly prescreen under the hopper that, along with the variable speed pan feeder, allows for better sizing of material with a variety of mesh options. McCloskey engineers have designed the J4 to meet the evolving requirements of today’s projects and operations. The J4 also features a 12” DSE Control Panel for high operational performance and reliability and 365 Site Connex telematics, where available

J4 Tech Specs

| Engine | 270kW (360Hp) – 310kW (416Hp) |

| Jaw Chamber (WxD) | 1060mm (42″) x 700mm (28”) |

| Feeder Width | 1064mm (41.9″) |

| Feeder Length | 4247mm (167.2″) |

| Grizzly Section Length | 1590mm (62.6″) |

| Hopper Volume | 5.8m³ (7.6yd³) |

| Stockpile Height | ————— |

| Main Conveyor | 3.91m (12′ 10″) |

| Side Conveyor | 3.44m (11′ 3.6″) |

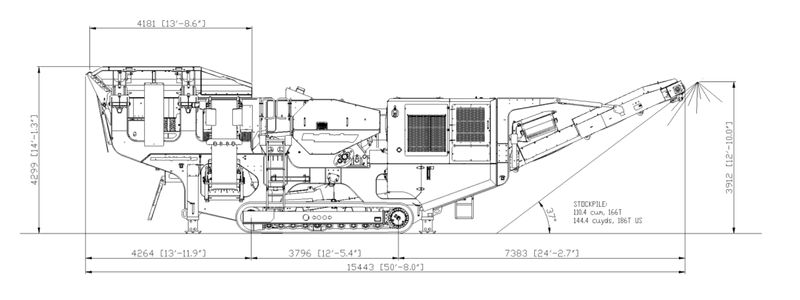

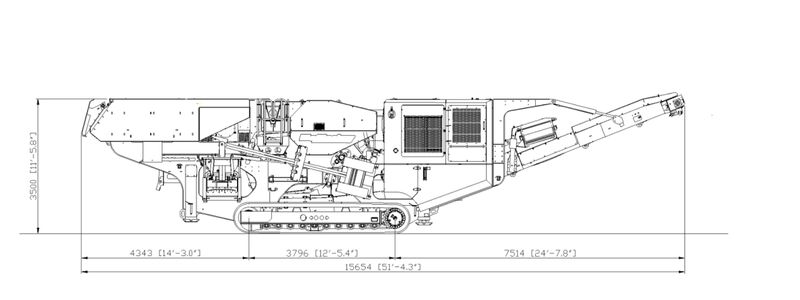

Transport

| Transport Height | 3.50m (11’ – 5.8”) |

| Transport Length | 15.80m (51′ – 8″) |

| Transport Width | 2.90m (9′ – 6″) |

| Weight | 51,280Kgs (113,050lbs) |